Resonant Gratings: R&D+fab global offer

Monolithic association of a surface relief or index modulation with a surface wave giving rise to high contrast, high polarization, wavelength, angular selectivity diffraction effects on free space waves. We offer vertically integrated solutions for the control of laser emission from 193 to 10600 nm wavelength, novel transducing mechanisms for sensors and electromagnetic effects for white light processing.

Grating fabrication technologies

Large exposure holographic bench

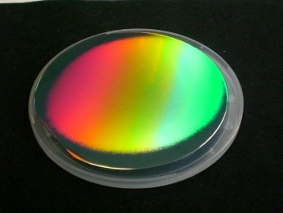

A large holographic has been installed using collimated beams which is able to write large grating up to 6 inches :

Various gratings can be fabricated:

• 1D&2D Sinusoidal, rectangular, and saw-tooth resist profiles

• Rectangular profiles with different duty-cycles

• Inverse trapeze resist profiles for lift-off

• Variable depth, variable period gratings

• Sinusoidal profile gratings in glass surfaces

Expanding the applicability domain of phase-mask lithography to extreme periods

Cooperation with the University of Eastern Finland, the University of Glasgow and the CNRS LPN within Networks of Excellence NEMO and ePIXnet. Collaboration with IS2M (Mulhouse)

Phase-mask lithography is an extremely convenient way of printing gratings which offers a number of advantages over the conventional grating lithography using a Mach-Zehnder scheme to give rise to an interferogram projected onto a resist-coated substrate although it is less flexible:

• The interferogram stability is immune to temperature, humidity, air turbulence effects,

• The interferogram period is independent of the exposure wavelength, only the exposure wave spatial coherence matters,

• The printed latent grating spatial frequency is twice as large as the phase-mask’s,

• The phase-mask can monolithically encompass features and functions which do not have to be controlled in a scan mode aimed at printing large area gratings

Phase-mask lithography has been successfully used for two decades mainly for the manufacturing of FBG Fiber Bragg Gratings. Using a phase-mask for printing a grating area on a flat surface is more demanding: not only does the 0th transmitted order have to be cancelled, but diffraction orders of order larger than 1 must be cutoff so that the interferogram spatial frequency spectrum only contains the harmonic created by the +1st and -1st orders. This implies that the printable range of period P is fairly limited: lambda/2 < P < lambda. This is much too narrow for a manufacturing technology.

We have acted to stretch the applicability domain towards small and large periods and broken the existing limits.

The short-period limit

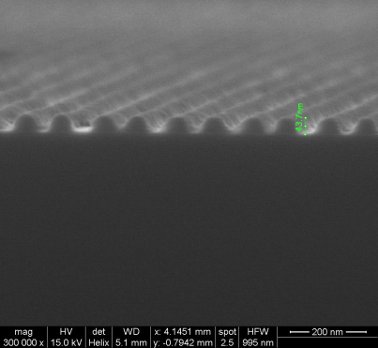

The short period limit results from the availability of a high index (layer) material at the shortest possible wavelength to enable the cancellation of the 0th transmitted order. After obtaining a 100 nm grating period grating by exposing a 200 nm period Si3N4-corrugation to the radiation of a doubled argon ion laser at 244 nm under immersion (Fig. 1).

The large period limit

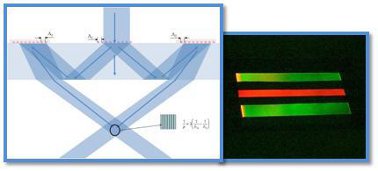

The large period limit was broken and pushed to infinity by designing a new phase-mask structure in the form of an integrated monolithic Mach-Zehnder all-grating interferometer implementing a spatial frequency heterodyne scheme as illustrated in Fig. 2. Such scheme suppresses all spurious diffraction orders and provides a 100% contrast interferogram with close to 80% efficiency.

Wide phase-mask printing of large area gratings with proportionate investment costs

Cooperation with the University of Eastern Finland

There is a need for large diffraction gratings in different scientific and business fields, for instance, more than 1 m2 for the compression of high energy femtosecond pulses with a period of 600-700 nm, more than 2 m2 for the lossless polarizer of large LCDs with a period of the order of 100 nm, for light processing windows and for solar light trapping into large light concentrator panels.

There are basically three manufacturing technologies for the printing of very large gratings. The first one is the projection of a large size interferogram where the investment costs increase dramatically with the grating area. The second one uses a large optical pattern generator commonly used for writing the masks in flat display photolithography; the achievable period is however limited to a large fraction of a micrometer and the achieved spatial coherence might be insufficient for printing highly coherent periodic patterns. A third approach is that of the precisely controlled scan of an elementary interferogram as used in the “Nanoruler” (MIT).

We are proposing yet a fourth approach [A method and installation for writing large gratings”, Patent number: EP 08291024 ] which resorts to the possibilities offered by the technology of phase-masks and extends the applicability of the latter to the extremes. Wide and long gratings can thus be printed upon the single scan of a wide phase mask in one direction under the sole real time control of the position along this direction and of the yaw of the printing phase-masks during the continuous scan. The position controls the temporal modulation of the exposure beam and the yaw measurement gives a correction of the phase-mask orientation. Such simple mechanical control is made possible by embarking most spatial coherence features of the future large grating on board the phase-mask. The phase-mask is illuminated normally by a simple s-polarized diverging light sheet with synchronously modulated top-hat intensity profile.

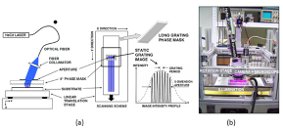

Fig. 3 a) and b) illustrate the wide phase-mask fabrication scheme and the scan of the latter for the exposure of a wide and long latent grating deposited onto a large substrate.

As there is no stringent requirement on the scanning mechanics, wide gratings of arbitrary length can in principle be printed without noticeable increase of the investment costs.

The principle has been demonstrated at reduced dimension with a 100 mm wide phase-mask written by e-beam followed by the RIE of a Si3N4 layer. The top-hat exposure light sheet at 442 nm wavelength was generated by a rotating DOE line generator to average the speckle and also by a micro-refractive element whose topography was made by e-beam variable dose exposure and proportional RIE.