Freeforms

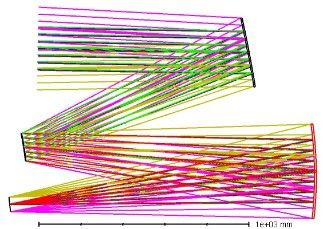

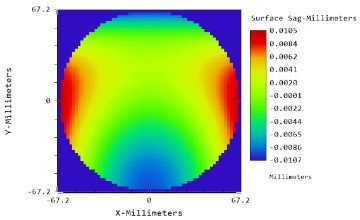

Optical diopters are almost exclusively spherical or axially symmetric surfaces fabricated under computer numerical control (CNC). Recently, surfaces without rotational symmetry, or more generally freeform surfaces emerged as a new paradigm based on current technological possibilities (such as multi-axial diamond turning) and modeling strategies. The number of degrees of freedom in optical system design is thereby considerably increased, paving the way for higher performance with fewer components and thus at a lower cost.

The concept is becoming an active field of research (both academic and industrial) addressing many applications in imaging and lighting. As regards modeling, strategies are still in infancy, for instance no established tolerancing strategy exists. Their relationship to manufacturing tools needs to be addressed specifically : how different freeform surface descriptions may yield advantages not only in various design challenges but also in supporting the tolerancing and manufacturing of these surfaces?

We tackle this topic via the Nodal Aberrations Theory, and simulation tools as Zemax Optics Studio.

In October 2017, we started a PhD devoted to freeforms for aerospace applications (with Thales Alenia Space and Sophia Conseil). In particular, we will study innovative fabrication methods of freeforms such as additive printing of ceramics and metals (with 3DCeram), and innovative metrology such as deflectometry (with Pr Yves Surrel).

Besides, we are working on the creation of a National competence center like those existing in Rochester (CeFO) and Jena (fo+).

Early works involved the study of freeform phase masks to extend the depth of field of imagers:

D. Kuang, T. Lépine, J. Tian, P. Dufouleur, Beam shaping with multiple-powered phase masks, Paper 9271-20, SPIE Cos Photonics Asia, Beijing, China, 9-11 october 2014

D. Kuang, Y. Cao, T. Lépine, W. Mi, Curved surface plasmon polariton excitation with shaped beam by fifth-power phase mask, IEEE Photonics journal, Volume 7, Number 6, December 2015