Article: High-Density Nanowells Formation in Ultrafast Laser-Irradiated Thin Film Metallic Glass

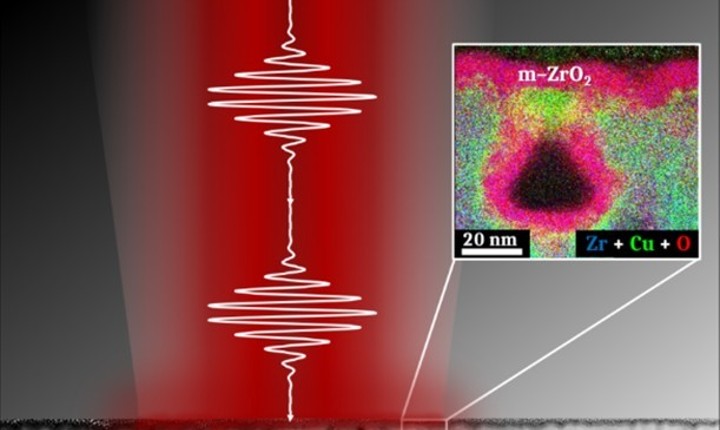

Image above: Nanowells generated on a thin layer of metallic glass irradiated by ultrafast laser pulses.

Last April, an article by the Laboratoire Hubert Curien’s Laser Matter Interaction team has been published in Nano-Micro Letters, a journal focussing on science, experiments, engineering, technologies and applications of nano- or microscale structure and system in various scientific disciplines.

The miniaturization of surfaces' structuring is a perpetual challenge as it allows to broaden the fields of applications in nanotechnology. Particularly, the process can find applications in biochemistry, biomedicine or renewable energies. More specifically, amorphous metals, also called "metallic glasses", are the subject of much research for they have unique characteristics such as a smooth surface without any roughness, a good mechanical behavior and an increased corrosion resistance. Their longevity makes them prone to be used for the manufacturing of, for example, small components present in watches, or as coatings for turbines. Their biocompatible properties also make them an ideal type of coating for surgical tools.

It is on thin film metallic glasses that our team has experimented and developed, in collaboration with the Jean Lamour Institute (University of Lorraine, CNRS), an ultrashort laser irradiation process allowing to modify their chemical properties and their topographical characteristics. The project initially aimed at creating periodic structuring at the nanometric scale -"nanorides” - on these coatings made with a selected composition of zirconium and copper (Zr65Cu35). An unexpected consequence of this work was the discovery of networks of dense nanowells, formed spontaneously on the surface of the irradiated zone, with dimensions as low as 20 nm. The flared shape of these wells proves to be ideal for ensuring the immobilization or the controlled release of chemical or biological compounds. In addition, the localization of the nanowells can be modulated thanks to the control of the initial morphology of the films deposited on their substrate by sputtering. Topographic functionalization is accompanied by structural functionalization, characterized by the creation of monoclinic zirconia nanocrystals that develop within the material.

This laser irradiation process therefore has promising application potential for the storage and gradual release of chemical or biological elements, allowed by the flared shape of the nanowells. Being able to control their size and their concentration on the surface would also allow to adapt them for targeted applications. One can imagine, for example, the development of an orthopaedic implant covered with a thin layer of metallic glass textured with nanowells. Bioactive liquids would thus be released in a local and controlled manner to avoid possible infections induced by the placement of this implant. Mastering the characteristics of these nanowells also opens the way to other applications related to the “wettability” of certain surfaces, for example in the medical field, but also for the waterproofing of electronic equipment.

Abstract

We present an effective approach for fabricating nanowell arrays in a one-step laser process with promising applications for the storage and detection of chemical or biological elements. Biocompatible thin films of metallic glasses are manufactured with a selected composition of Zr65Cu35, known to exhibit remarkable mechanical properties and glass forming ability. Dense nanowell arrays spontaneously form in the ultrafast laser irradiation spot with dimensions down to 20 nm. The flared shape observed by transmission electron microscopy is ideal to ensure chemical or biological material immobilization into the nanowells. This also indicates that the localization of the cavitation-induced nanopores can be tuned by the density and size of the initial nanometric interstice from the columnar structure of films deposited by magnetron sputtering. In addition to the topographic functionalization, the laser-irradiated amorphous material exhibits structural changes analyzed by spectroscopic techniques at the nanoscale such as energy-dispersive X-ray spectroscopy and electron energy loss spectroscopy. Results reveal structural changes consisting of nanocrystals of monoclinic zirconia that grow within the amorphous matrix. The mechanism is driven by local oxidation process catalyzed by extreme temperature and pressure conditions estimated by an atomistic simulation of the laser-induced nanowell formation.

Read the full article here.