Article: Super-efficient drilling of metals with ultrafast non diffractive laser beams

One of the Laboratoire Hubert Curien’s Laser-Matter Interaction team latest publications, lead by Huu Dat Nguyen, has appeared in Scientific Reports, from the publishers of Nature. The team have developed an efficient laser-based method for the deep drilling of metals, based on a self-sustained propagation of non-diffractive beams. Simulations of beam propagation and interaction with matter (E. Morenos and A. Rudenko) support the experimental observations.

Abstract

A highly efficient drilling process is found in non-transparent metallic materials enabled by the use of non-diffractive ultrafast Bessel beams. Applied for deep drilling through a 200 μm-thick steel plate, the Bessel beam demonstrates twofold higher drilling efficiency compared to a Gaussian beam of similar fluence and spot size. Notwithstanding that surface ablation occurs with the same efficiency for both beams, the drilling booster results from a self-replication and reconstruction of the beam along the axis, driven by internal reflections within the crater at quasi-grazing incidence, bypassing potential obstacles. The mechanism is the consequence of an oblique wavevectors geometry with low angular

dispersion and generates a propagation length

beyond the projection range allowed by the geometry of the channel. With only the main lobe being selected by the channel entrance, side-wall reflection determines the refolding of the lobe on the axis, enhancing and replicating the beam multiple times inside the channel. The process is critically assisted by the reduction of particle shielding enabled by the intrinsic self-healing of the Bessel beam. Thus, the drilling process is sustained in a way which is uniquely different from that of the conventional Gaussian beam, the latter being damped within its Rayleigh range. These mechanisms are supported and quantified by Finite Difference Time Domain calculations of the beam propagation. The results show key advantages for the quest towards efficient laser drilling and fabrication processes.

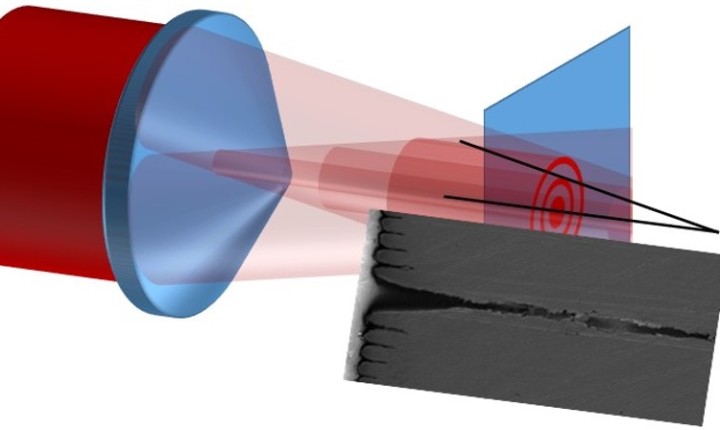

Diagram illustrating the generation of a non-diffractive laser beam, and its drilling result.

Image above:

Diagram illustrating the generation of a non-diffractive laser beam, and its drilling result.

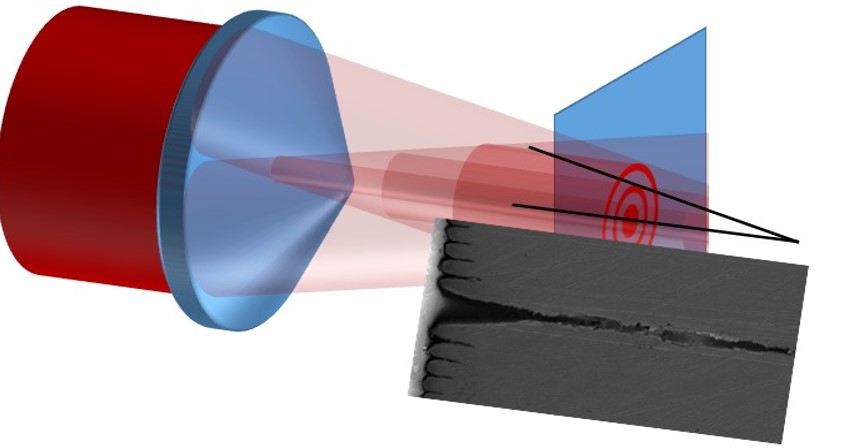

Schematic of the Bessel-Gaussian beam configuration, including an axicon and a standard 4f telescopic system (an achromatic lens and a microscope objective). The inset describes standard parameters of the Bessel beam with D0 is the incident Gaussian beam diameter, α is the physical or base angle of the axicon, Zb is the Bessel length, θ is the half cone angle, k is the wave vector, and 2rb is the diameter of the beam central core.

Image above:

Schematic of the Bessel-Gaussian beam configuration, including an axicon and a standard 4f telescopic system (an achromatic lens and a microscope objective). The inset describes standard parameters of the Bessel beam with D0 is the incident Gaussian beam diameter, α is the physical or base angle of the axicon, Zb is the Bessel length, θ is the half cone angle, k is the wave vector, and 2rb is the diameter of the beam central core.

Read the full article https://www.nature.com/articles/s41598-022-05967-5 .